- Home

- Articles

- Architectural Portfolio

- Architectral Presentation

- Inspirational Stories

- Architecture News

- Visualization

- BIM Industry

- Facade Design

- Parametric Design

- Career

- Landscape Architecture

- Construction

- Artificial Intelligence

- Sketching

- Design Softwares

- Diagrams

- Writing

- Architectural Tips

- Sustainability

- Courses

- Concept

- Technology

- History & Heritage

- Future of Architecture

- Guides & How-To

- Art & Culture

- Projects

- Interior Design

- Competitions

- Jobs

- Store

- Tools

- More

- Home

- Articles

- Architectural Portfolio

- Architectral Presentation

- Inspirational Stories

- Architecture News

- Visualization

- BIM Industry

- Facade Design

- Parametric Design

- Career

- Landscape Architecture

- Construction

- Artificial Intelligence

- Sketching

- Design Softwares

- Diagrams

- Writing

- Architectural Tips

- Sustainability

- Courses

- Concept

- Technology

- History & Heritage

- Future of Architecture

- Guides & How-To

- Art & Culture

- Projects

- Interior Design

- Competitions

- Jobs

- Store

- Tools

- More

Whole House Customization in China: A Smart Choice for Global Builders and Designers

Table of Contents Show

- Understanding Whole House Customization in China

- Why Overseas Clients Prefer Whole House Customization from China

- The Advantage of a Chinese Building Material Warehouse

- How Turnkey Interior Design Solutions Simplify Global Projects

- Innovation Driving China’s Customization Industry

- Overcoming Common Concerns in Overseas Sourcing

- How to Start a Whole House Customization Project in China

- The Future of Whole House Customization in Global Markets

- Conclusion

- Chinese Building Material Warehouse: Complete Sourcing Guide for Global Builders

- How to Verify Reliable Suppliers

- Common Challenges and Practical Solutions

- 7-Step Sourcing Process

- Frequently Asked Questions

- Who Benefits Most from Chinese Building Material Warehouses?

- Conclusion: Making Chinese Building Material Warehouses Work for Your Projects

In today’s rapidly evolving construction and interior design world, whole house customization in China is reshaping how global developers and designers approach residential and commercial projects. With a strong foundation in custom furniture manufacturing, OEM production, and streamlined B2B sourcing, China has established itself as a leader in personalized living solutions.

International builders and retailers now depend on Chinese manufacturers for premium cabinetry, furniture, lighting, and flooring that reflect modern design trends. The country’s unmatched blend of innovation, affordability, and large-scale efficiency makes it the preferred partner for global clients seeking high-quality, fully customized home interiors.

Understanding Whole House Customization in China

Whole house customization refers to designing every detail of a living space to match the homeowner’s preferences, from color schemes and materials to furniture layouts and lighting fixtures. It moves beyond the limitations of off-the-shelf products and introduces complete design flexibility.

Chinese manufacturers have refined this concept through digital technologies like 3D modeling, CNC machining, and AI-driven design systems. The process includes concept development, prototype creation, custom furniture manufacturing, and international export. For overseas clients, this results in:

- A consistent design theme across multiple projects.

- Reduced procurement time and cost through one-stop B2B sourcing.

- Access to exclusive materials unavailable in local markets.

Why Overseas Clients Prefer Whole House Customization from China

International property developers and design firms increasingly turn to China for complete customization services. Here’s why:

1. Cost-Effective Production with Premium Quality

China’s large-scale production capacity and advanced logistics make it possible to offer superior quality at a competitive price. Manufacturers leverage automation, bulk material sourcing, and streamlined labor to deliver outstanding value for global projects.

2. Advanced Manufacturing & OEM Production Capabilities

Chinese factories utilize state-of-the-art tools like laser cutting and robotic assembly to maintain precision and consistency. Through OEM production, global brands can even customize designs and label products under their own brand names, offering a major edge in international markets.

3. Wide Range of Designs and Materials

From contemporary minimalism to European luxury, Chinese designers provide unmatched flexibility. Clients can choose from thousands of wood types, laminates, finishes, and eco-friendly materials, ensuring the perfect match for any design concept or cultural preference.

4. Strong Logistics and Global Shipping Support

With decades of experience in international trade, China’s export network ensures timely and secure deliveries. Partnering with experienced freight forwarders guarantees that materials and furniture reach clients safely, no matter the project scale.

The Advantage of a Chinese Building Material Warehouse

One of the most significant benefits for overseas clients is the Chinese building material warehouse system. These warehouses act as centralized sourcing hubs where buyers can find tiles, cabinetry, flooring, and more, all under one roof.

This integrated model allows international clients to compare materials, test product quality, and place consolidated orders, reducing time and cost. Many warehouses feature digital inventory systems that enable clients to track shipments in real time and request custom packaging for export.

For builders managing multiple projects across countries, this approach simplifies supply chain management and ensures a consistent quality standard across all developments.

How Turnkey Interior Design Solutions Simplify Global Projects

Beyond manufacturing, many firms in China now offer turnkey interior design solutions, providing a complete “concept-to-installation” service for overseas clients. These solutions ensure design consistency and reduce project complexity.

The process often includes:

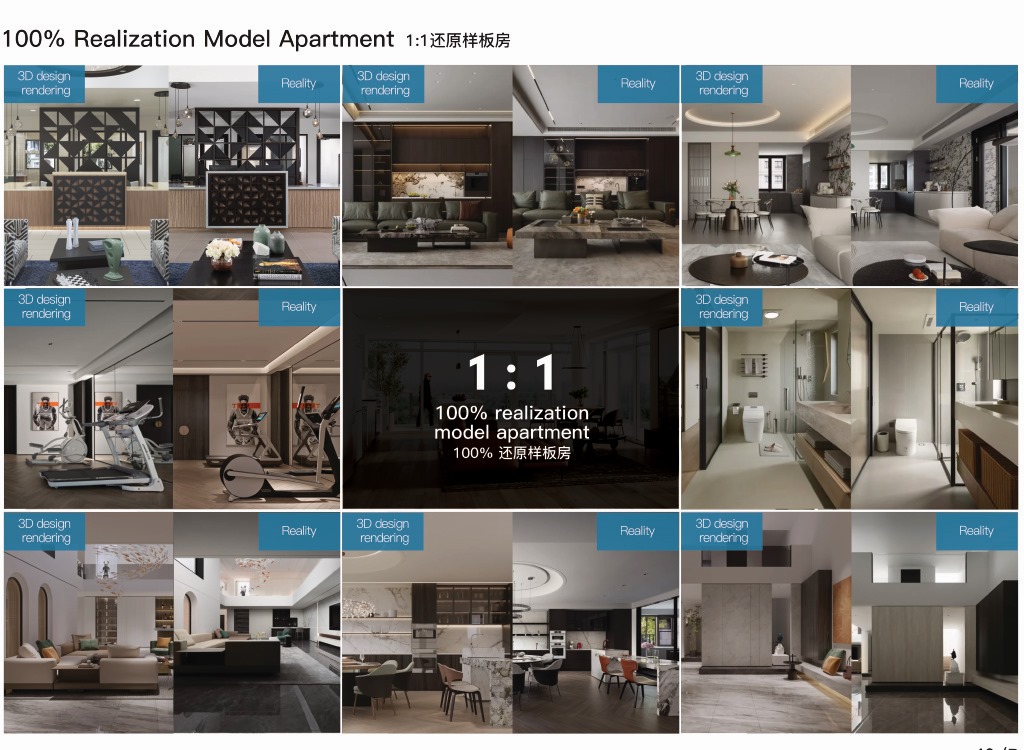

- 3D Visualization: Virtual tours and renderings to finalize design elements.

- Material Coordination: Perfect alignment of furniture, colors, and flooring.

- Production Supervision: Dedicated project managers oversee the entire manufacturing process.

- Shipping & Installation: Products are securely packed, shipped, and assembled on-site for final delivery.

This end-to-end model saves clients valuable time, reduces miscommunication, and guarantees the desired results without requiring constant on-ground supervision.

Innovation Driving China’s Customization Industry

The whole house customization industry in China thrives on continuous innovation. Today, factories are integrating AI-assisted design software, parametric modeling, and sustainable production methods to meet global expectations for personalization and eco-friendliness.

Some notable trends include:

- Smart Home Integration: Embedding automation and IoT systems into interior designs.

- Eco-Friendly Materials: Using bamboo composites, recycled wood, and water-based finishes.

- Modular Construction: Flexible components that fit diverse layouts and room sizes.

- Lean Manufacturing: Reducing waste and maximizing efficiency.

These forward-thinking innovations make China not just a manufacturer but a creative partner in shaping the future of global home customization.

Overcoming Common Concerns in Overseas Sourcing

While some international clients initially worry about communication barriers or quality issues, China’s B2B sourcing ecosystem has evolved to resolve these challenges effectively:

- Language & Communication: Bilingual teams ensure smooth coordination with overseas partners.

- Quality Control: Third-party inspection agencies certify products before shipment.

- Secure Transactions: Transparent contracts and verified payment systems protect buyers.

- After-Sales Support: Dedicated teams handle inquiries, replacements, and after-installation services.

Such professional systems build long-term trust and reliability, encouraging global firms to maintain ongoing partnerships with Chinese suppliers.

How to Start a Whole House Customization Project in China

Starting a whole house customization project in China is straightforward and efficient. The process typically includes:

- Initial Consultation: Discuss project goals, layout preferences, and budget.

- Design & Proposal: Receive visual concepts, mood boards, and material samples.

- Quotation & Agreement: Confirm pricing, production details, and delivery timelines.

- Production & Inspection: Manufacturing begins under expert supervision.

- Packaging & Export: Secure shipping by sea or air freight.

- On-Site Installation: Optional overseas installation and setup services.

This transparent process helps clients maintain control over every stage from design to delivery.

The Future of Whole House Customization in Global Markets

As sustainability and personalization continue to drive global trends, whole house customization in China is set to play an even greater role. With digital showrooms, AI-powered manufacturing, and eco-conscious designs, Chinese firms are becoming strategic partners for global developers.

Through their expertise in custom furniture manufacturing, OEM production, and B2B sourcing, Chinese manufacturers are setting new benchmarks for quality and innovation in global home design.

Conclusion

China’s rise as a hub for whole house customization is transforming how the world builds and decorates. Its blend of expert craftsmanship, modern technology, and streamlined Chinese building material warehouse systems offers global clients unbeatable convenience and consistency.

By integrating turnkey interior design solutions and advanced custom furniture manufacturing, overseas developers and design firms can bring projects to life seamlessly from concept to completion. With its proven reliability, scalability, and innovation-driven mindset, China remains the ultimate partner for global builders seeking personalized, high-quality living spaces.

Chinese Building Material Warehouse: Complete Sourcing Guide for Global Builders

Why Choose a Chinese Building Material Warehouse

A Chinese building material warehouse provides international contractors and developers with centralized sourcing that reduces material costs by 30-50% compared to local suppliers. These warehouses in Foshan offer tiles, flooring, cabinetry, lighting, and custom furniture through direct factory channels.

Professional sourcing companies handle quality control, consolidate shipments, and coordinate multiple manufacturers—eliminating the complexity of managing dozens of supplier relationships.

Key Benefits:

- 30-50% cost savings vs local suppliers

- One-stop sourcing for complete material lists

- Factory verification and quality inspections

- Mixed-container loading for cost efficiency

- Fast turnaround: samples in 5-7 days, bulk orders in 20-30 days

- Flexible MOQ starting from 1 container

Price Comparison: China vs Local Suppliers

Understanding real savings helps in project planning:

| Material | China Price | Local Price | Savings | MOQ |

| Porcelain Tiles | $8-12/m² | $18-25/m² | 45% | 500m² |

| SPC Flooring | $12-18/m² | $25-35/m² | 48% | 1000m² |

| Kitchen Cabinets | $180-280/lm | $400-600/lm | 55% | 10 sets |

| LED Fixtures | $15-45/unit | $40-90/unit | 56% | 100 units |

| Custom Furniture | $320-580/set | $800-1500/set | 65% | 20 sets |

*Prices exclude shipping. Add $2,000-5,000 per 40ft container.

Real Project: A 150-unit Dubai apartment development sourced flooring, cabinetry, and fixtures through a Foshan warehouse, saving $287,000 compared to local UAE suppliers—even after shipping and import duties.

What You Can Source from Chinese Building Material Warehouses

Professional warehouses stock export-grade materials across multiple categories:

Flooring: Ceramic tiles, SPC/laminate flooring, hardwood, mosaics

Cabinetry: Kitchen cabinets, vanities, wardrobes, custom millwork

Doors & Windows: Aluminum windows, interior doors, security doors

Lighting: LED downlights, chandeliers, smart lighting systems

Furniture: Residential sets, hotel FF&E, OEM/ODM custom production

Hardware: Door handles, cabinet hardware, bathroom accessories

Most established warehouses work with 200-500 verified factories, allowing buyers to compare options and match specific project requirements.

Turnkey Interior Design Solutions from Chinese Building Material Warehouses

Beyond materials, many warehouses now offer integrated design services—particularly valuable for developers managing multiple units or properties.

Complete Services Include:

- 3D visualization and space planning

- Material coordination and color matching

- Custom furniture design and OEM branding

- Quality control and pre-shipment inspections

- Consolidated shipping from multiple factories

- Optional on-site installation in select markets

Case Study: An international hotel group renovating 8 properties across Southeast Asia partnered with George’s Furniture, a Foshan-based sourcing company, to supply coordinated furniture packages and fixtures. The centralized approach maintained brand consistency across all locations while reducing procurement time from 6 months to 11 weeks. The project included custom-designed lobby furniture, 240 guest room sets, and lighting fixtures—totaling $680,000 in materials with seamless coordination across multiple factories.

This turnkey model ensures design consistency—critical when managing large-scale hospitality or residential developments.

How to Verify Reliable Suppliers

Not all sourcing companies offer the same level of service. Use this verification checklist:

Essential Checks:

- ✓ Valid business license (5+ years operational history preferred)

- ✓ Physical warehouse location (request video tour)

- ✓ List of partner factories with contact information

- ✓ Documented quality control procedures

- ✓ 3-5 verifiable client references

- ✓ Responsive communication (within 24 hours)

Red Flags to Avoid:

- ❌ No physical warehouse or showroom

- ❌ Reluctance to share factory details

- ❌ Pressure for large deposits before samples

- ❌ Prices significantly below market rates

- ❌ No written quality guarantee or inspection process

Common Challenges and Practical Solutions

Quality Consistency

Require pre-production samples and third-party inspections ($250-400 per visit). Include penalty clauses in purchase contracts.

Communication Barriers

Work with companies providing English-speaking staff. Use detailed drawings and confirm all agreements in writing. Schedule regular video calls for product reviews.

Shipping Times

Add 2-3 weeks buffer to estimates. Typical sea freight: USA (25-35 days), Europe (30-40 days), Middle East (18-25 days), Australia (20-30 days).

Total Cost Calculation

Formula: Product Cost + Shipping ($2,000-5,000/container) + Insurance (0.5-1%) + Import Duties (0-30%) + Port Fees ($300-800) + Broker Fees ($200-500) = Landed Cost

7-Step Sourcing Process

Step 1: Project Documentation (1-2 days)

Share floor plans, design concepts, quantities, budget, and timeline requirements.

Step 2: Material Selection (3-5 days)

Review catalogs, factory information, and alternative options at different price points.

Step 3: Sample Order (5-7 days + shipping)

Request physical samples for evaluation. Cost: $50-200 per item (often refundable with bulk orders).

Step 4: Quotation Review (2-3 days)

Confirm pricing, payment terms (typically 30% deposit, 70% before shipping), lead times, and warranty coverage.

Step 5: Purchase Order (1-2 days)

Finalize the contract with detailed specifications, quality standards, delivery terms, and penalty clauses.

Step 6: Production & QC (15-40 days)

Monitor progress with weekly photo updates. Schedule pre-shipment inspections and review reports before final payment.

Step 7: Shipping & Delivery (20-40 days)

Coordinate export documents, customs clearance, and final site delivery.

Total Timeline: 9-17 weeks (2-4 months)

Frequently Asked Questions

Q: What’s the minimum order value to make China sourcing worthwhile?

A: Generally $20,000-30,000 in materials. Below this threshold, shipping costs may outweigh savings unless ordering highly specialized items.

Q: How do I handle product defects?

A: Reputable suppliers typically provide 2-5% extra quantity for minor defects, replacement in next shipment, or partial refunds for non-critical issues. Document all defects with photos within 7 days of delivery.

Q: What payment methods are standard?

A: Bank wire transfer (T/T) is most common—30% deposit, 70% before shipping. Letter of Credit recommended for orders exceeding $100,000. Avoid Western Union or 100% upfront payments.

Q: What certifications should I require?

A: Depends on destination. USA: CARB, UL; Europe: CE, REACH; Middle East: SASO, ESMA; Australia: AS/NZS, WaterMark. Always verify your country’s specific import requirements before ordering.

Q: Can I visit factories before committing?

A: Yes, highly recommended for orders over $50,000. Most sourcing companies arrange factory tours, accommodation, and translator services. Budget $1,500-3,000 for a 3-5 day visit.

Who Benefits Most from Chinese Building Material Warehouses?

Ideal Client Types:

- Real estate developers with 10+ unit projects

- Construction companies handling commercial build-outs

- Interior design agencies managing multiple projects simultaneously

- Hotel and hospitality groups requiring FF&E procurement

- Furniture brands seeking OEM/ODM manufacturing

When Local Sourcing Makes More Sense:

- Projects under $20,000 in material value

- Urgent timelines under 4 weeks

- Projects requiring extensive post-installation support

- Regulatory mandates for domestically-produced materials

Conclusion: Making Chinese Building Material Warehouses Work for Your Projects

Chinese building material warehouses provide international builders with practical cost reduction while maintaining access to diverse product selections. For projects valued at $30,000+ in materials, the 30-50% savings typically justify the coordination effort—particularly when partnering with experienced sourcing companies that handle quality control, logistics, and turnkey interior design solutions.

Before committing to overseas procurement, conduct thorough cost-benefit analysis including shipping, import duties, and time investment. For many developers and contractors, the efficiency and product variety available through Foshan-based warehouses like George’s Furniture make them viable alternatives to traditional local suppliers.

When selecting a sourcing partner, prioritize companies with established factory networks, documented quality control processes, and verifiable client references. The right partner transforms complex international procurement into a streamlined, predictable process.

Ready to explore sourcing options? Compare multiple providers, verify credentials thoroughly, and select partners with proven track records in your specific material categories and target markets.

Information current as of November 2025. Prices, shipping times, and import regulations vary by region and market conditions. Always verify current requirements with customs brokers and sourcing partners before finalizing orders.

illustrarch is your daily dose of architecture. Leading community designed for all lovers of illustration and drawing.

Submit your architectural projects

Follow these steps for submission your project. Submission FormLatest Posts

Understanding Structural Diagrams in Architecture: Load, Logic, and Form

Structural diagrams translate the invisible forces inside a building into clear visual...

Top 10 Examples of Modern Vernacular Architecture Around the World

Explore 10 outstanding modern vernacular architecture buildings from six continents, including works...

How to Plan a Fun Birthday Party at Your Home

Table of Contents Show Theme SelectionBouncy Castle RentalInvitationsFood and DrinksActivities and GamesDecorationsParty...

Top 10 Most Inspiring Women in Architecture

Explore the remarkable achievements of women in architecture who transformed the profession...

Leave a comment