- Home

- Articles

- Architectural Portfolio

- Architectral Presentation

- Inspirational Stories

- Architecture News

- Visualization

- BIM Industry

- Facade Design

- Parametric Design

- Career

- Landscape Architecture

- Construction

- Artificial Intelligence

- Sketching

- Design Softwares

- Diagrams

- Writing

- Architectural Tips

- Sustainability

- Courses

- Concept

- Technology

- History & Heritage

- Future of Architecture

- Guides & How-To

- Art & Culture

- Projects

- Interior Design

- Competitions

- Jobs

- Store

- Tools

- More

- Home

- Articles

- Architectural Portfolio

- Architectral Presentation

- Inspirational Stories

- Architecture News

- Visualization

- BIM Industry

- Facade Design

- Parametric Design

- Career

- Landscape Architecture

- Construction

- Artificial Intelligence

- Sketching

- Design Softwares

- Diagrams

- Writing

- Architectural Tips

- Sustainability

- Courses

- Concept

- Technology

- History & Heritage

- Future of Architecture

- Guides & How-To

- Art & Culture

- Projects

- Interior Design

- Competitions

- Jobs

- Store

- Tools

- More

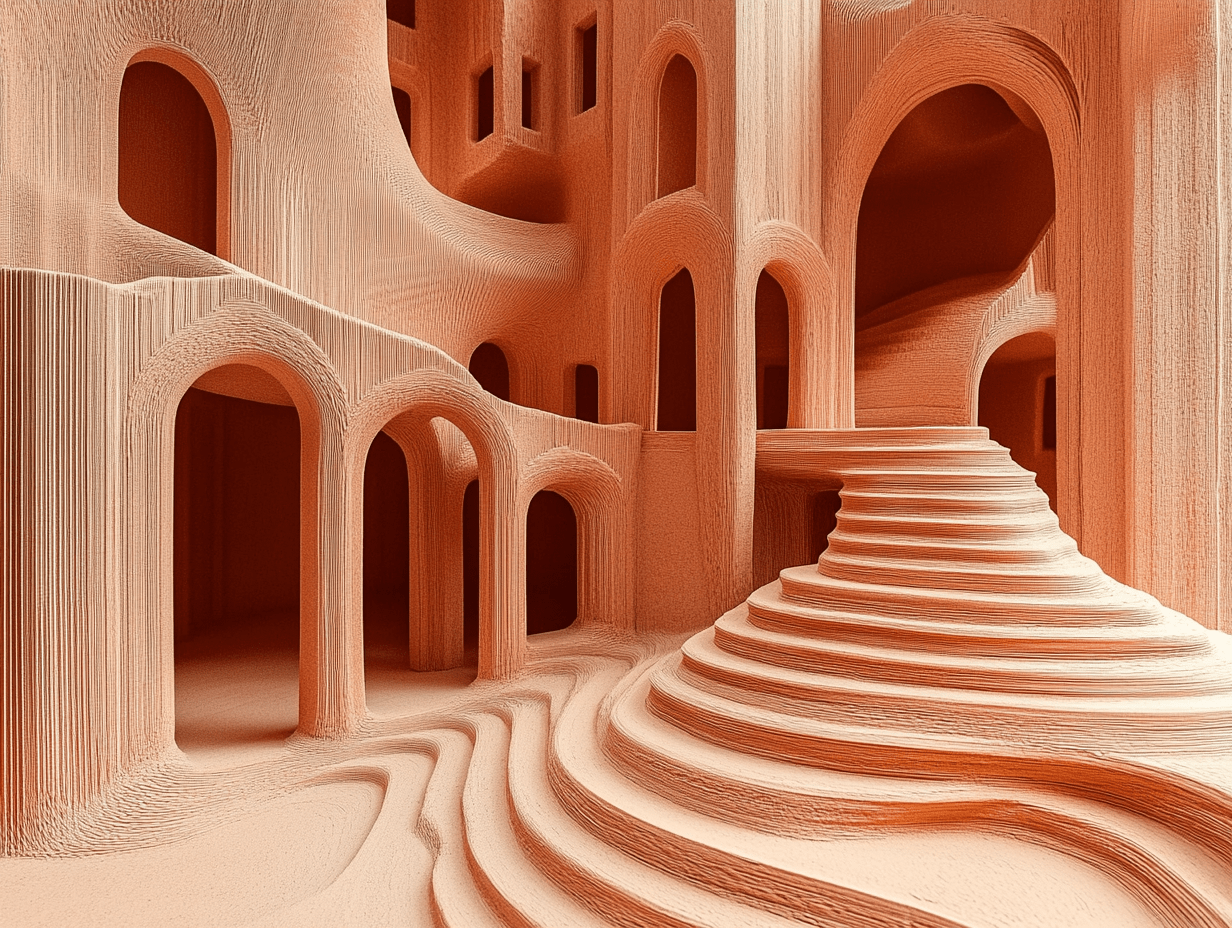

The Future of 3D Printed Buildings: Innovations, Benefits, and Challenges

Imagine a world where constructing a house takes just a single day. Thanks to the advancements in 3D printing technology, this futuristic vision is rapidly becoming our reality. From Europe’s first 3D printed building to Spain’s pioneering 3D printed concrete bridge, the construction industry is undergoing a revolution.

3D printing isn’t just about speed; it’s also about innovation and sustainability. For instance, restoration projects like the Snop Sheaf fountain in Russia showcase how 3D printing can blend modern technology with historical preservation. With the capability to print buildings at a rate of up to 35 meters per hour, the potential for this technology seems limitless.

Join us as we explore how 3D printed buildings are reshaping architecture, reducing construction time, and offering sustainable solutions for the future.

Table of Contents

ToggleUnderstanding 3D-Printed Buildings

What Are 3D-Printed Buildings?

3D-printed buildings are structures created using additive manufacturing techniques. Instead of traditional construction methods, 3D-printed buildings are made by layering materials, usually concrete, layer by layer until the desired shape is achieved. This method offers significant advantages, including reduced construction time, lower costs, and the ability to create complex designs that are difficult or impossible with traditional methods. Examples of 3D-printed buildings vary from houses and office spaces to bridges and fountains.

How Does 3D Printing in Construction Work?

The most common 3D printing technology for construction involves a robotic arm that extrudes concrete while moving back and forth. The robotic arm is guided by digital blueprints, ensuring precision in the building process. During powder binding, layers of powder are solidified to form the desired object. Additive welding, demonstrated in Amsterdam with a full-scale metal bridge, involves joining materials layer by layer.

The process begins with a digital model of the structure designed on a computer. This model is then fed into the 3D printer, which interprets the data and lays down material accordingly. Binding liquid is injected under the surface of the regolith with a 3D printer nozzle, trapping droplets via capillary forces. Depending on the printing technology, materials such as concrete, metal, or even simulated lunar material can be used.

Projects like Behrokh Khoshnevis’ claim to print a house in a day illustrate the potential of 3D printing in construction. By January 2013, advancements allowed the printing of 2 meters of building material per hour, with future models expected to reach up to 3.5 meters per hour. These innovations enable the rapid development of buildings, significantly impacting construction efficiency and sustainability.

Benefits of 3D-Printed Buildings

Cost Efficiency

3D-printed buildings offer significant cost savings in construction. Traditional methods involve multiple labor-intensive steps, each adding to the overall expense. In contrast, additive manufacturing can substantially reduce labor costs by automating much of the construction process. For example, printing a house in 20 hours eliminates many of the manual tasks that typically extend timelines and inflate budgets. Furthermore, the precision of 3D printing minimizes material waste, directly cutting costs and improving project budget management.

Speed of Construction

Speed is a standout advantage of 3D-printed buildings. Traditional construction projects can take months or even years to complete, whereas advanced 3D printers can expedite this significantly. By 2013, technology was in place to print 2 meters of building material per hour, with newer models increasing this rate to 3.5 meters per hour. This capability means that entire structures, such as houses, can be built in just days instead of weeks. The rapid assembly not only accelerates project timelines but also reduces labor overhead and site maintenance costs.

Environmental Impact

The environmental benefits of 3D-printed buildings are notable. This technology inherently promotes sustainability by reducing waste and optimizing resource usage. Traditional construction waste accounts for a significant portion of landfill content, whereas 3D printing’s precise material application conserves resources. Innovations in concrete 3D printing, coupled with traditional wood framing, highlight a hybrid approach that marries efficiency with eco-friendly practices. Additionally, 3D printing allows for the use of sustainable materials and can integrate designs that enhance energy efficiency, further reducing the ecological footprint of new buildings.

Challenges in 3D-Printed Construction

Regulatory and Code Compliance

Ensuring 3D-printed structures meet existing building codes and regulations remains challenging. Many current codes are based on traditional construction methods, necessitating new standards for 3D printing. Without established guidelines, it’s tough to verify the safety and durability of these structures. Regulatory bodies need to adapt to encompass 3D printing technologies, but this process is slow and complicated due to the novelty and uniqueness of the methods involved.

Material Limitations

3D-printed construction currently utilizes a limited range of materials, primarily including concrete, plastics, and composites. This constrains the types of structures that can be created and impacts their longevity and strength. The development of new materials compatible with 3D printing is ongoing, but until a broader spectrum is available, this limitation hampers the widespread adoption of the technology.

Technological Barriers

Despite advancements, technology in 3D-printed construction still faces significant hurdles. Printer size limits the scale of projects, although some large structures are feasible. Moreover, quality control remains a concern due to the absence of standardized procedures to ensure structural integrity. High investment costs for printers, coupled with the need for skilled labor to operate them, further impede the technology’s broader application. Ensuring consistent quality and overcoming these technological barriers is crucial for the industry’s growth.

Case Studies and Current Examples

Residential Structures

Project Milestone in Eindhoven, Netherlands, is a prime example of 3D printed residential structures. Consisting of five 3D printed concrete dwellings, this project represents the world’s first commercial housing project using this medium. The first dwelling, a 1,011-square-foot structure, was printed onsite in 120 hours as 24 separate parts. These houses, resembling elongated boulders with smooth, rounded edges, blend seamlessly with Eindhoven’s techy backdrop. The structures feature extra-thick insulation and connect to the heat grid, achieving high marks in energy efficiency according to 3D Natives. The first tenants, Elize Lutz and Harrie Dekkers, received their keys on April 30, 2021.

Commercial Projects

In a notable commercial project, a 3D printed architectural structure was constructed using simulated lunar material. Tests in a large vacuum chamber simulated extraterrestrial conditions. The technique involved injecting binding liquid under the surface of the regolith with a 3D printer nozzle, trapping 2 millimeter droplets beneath the surface via capillary forces. The printer used was D-Shape, a 3D printer capable of creating large-scale structures with high precision.

Behrokh Khoshnevis, a key figure in the 3D printing industry, has claimed since 2006 that it’s possible to 3D print a house in a day. By January 2013, working versions of this technology were printing 2 meters (6 feet 7 inches) of building material per hour. The next generation of printers was proposed to reach speeds of 3.5 meters (11 feet) per hour, enough to complete a building in a week. One significant commercial project includes a fountain designed by Nikolai Dydykin, renovated with 3D printing technology. The Snop Sheaf fountain, originally rectangular, was reshaped into a round form with updates to the backlight system. The parapet, featuring internal communication channels, was printed by the AMT construction printer, highlighting the application’s versatility in both artistic and practical domains.

The Future of 3D-Printed Buildings

Innovations on the Horizon

3D printing technology in construction promises several revolutionary innovations. New materials, such as simulated lunar concrete, enhance the durability and adaptability of structures. For example, Project Milestone in Eindhoven showcases how residential homes can be built with high energy efficiency using 3D printing. Companies are exploring multifunctional robots that print complex architectural features in one continuous operation. This improvement reduces labor costs and speeds up production.

Further, advancements in printer technology, like those from Behrokh Khoshnevis, aim to print 11 feet of material per hour, enabling the completion of a building in a single week. With each new iteration, these printers gain greater precision, enhancing the quality and safety of 3D-printed buildings. Additionally, innovations in software allow for real-time monitoring and adjustments during the printing process, improving efficiency and minimizing errors.

Potential Market Growth

The market for 3D-printed buildings is set to grow significantly. According to data from various industry reports, the global market for 3D printing in construction is expected to reach billions of dollars within the next decade. This growth follows increased adoption in commercial and residential projects. For example, the construction of entire communities using 3D printing is now a reality in multiple countries.

Europe remains a central hub for 3D construction innovation, housing conferences dedicated to showcasing the latest advancements. Properties featuring 3D-printed components offer advantages such as reduced construction waste and lowered carbon footprints, attracting environmentally conscious developers. Moreover, regulatory bodies are beginning to offer more clear guidelines, which facilitates faster project approval and implementation.

With ongoing research and development, coupled with increasing market demand, the future of 3D-printed buildings appears promising and poised for rapid expansion.

Conclusion

3D-printed buildings represent a promising frontier in construction, offering numerous advantages over traditional methods. The advancements in materials, printer technology, and design capabilities contribute to significantly faster building times and reduced costs. For instance, working versions of 3D-printing technology can print up to 2 meters of building material per hour, with future generations potentially achieving speeds of 3.5 meters per hour.

Notable projects like Europe’s first 3D-printed building and Spain’s 3D-printed concrete bridge underscore the technology’s revolutionary impact. These examples highlight benefits including enhanced efficiency, sustainability, and innovation. For residential and commercial projects, the cost-effectiveness and speed of 3D printing offer compelling advantages, making it an attractive option for a wide range of applications.

However, the technology is not without its challenges. Factors such as the type of printer, quality of materials, and environmental conditions can influence the accuracy of 3D-printed structures. Regulatory issues and the need for robust standards also present hurdles that need to be addressed to facilitate broader adoption.

Research and development are driving continuous improvements in the field. Advancements in simulated lunar concrete and multifunctional robots show promise for complex architectural features. The projected market growth, expected to reach billions of dollars, signals increasing adoption of 3D-printed buildings in both commercial and residential sectors globally.

Europe continues to be a hub for 3D construction innovation, with clearer regulatory guidelines helping to accelerate project approvals. Properties featuring 3D-printed components benefit from reduced waste and lower carbon footprints, aligning with global sustainability goals.

The future of 3D-printed buildings looks promising, with ongoing research, technological advancements, and growing market demand driving the industry. As we look ahead, the potential for 3D-printed buildings to reshape the construction landscape remains vast and exciting.

- 3D printed building materials

- 3D Printed Buildings

- 3D printing construction companies

- 3D printing construction technology

- 3D printing in construction industry trends

- Benefits of 3D printed homes

- Challenges in 3D printing for construction

- Cost of 3D printed buildings

- Eco-friendly 3D printed houses

- Future of construction 3D printing

- Innovations in 3D printed architecture

- Sustainable 3D printed homes

A licensed architect with hands-on studio experience, I translate complex design ideas into clear, engaging stories for a global audience. As a seasoned content writer and editor, I craft articles, project features, and thought-leadership pieces that illuminate emerging technologies, sustainable practices, and cutting-edge design trends—always with an architect’s eye for detail, accuracy, and narrative flow. My goal is to bridge practice and publication, giving fellow professionals and curious readers alike the insight and inspiration they need to push architectural boundaries.

Submit your architectural projects

Follow these steps for submission your project. Submission FormLatest Posts

Best 3D Scanners for Construction Site Digitization

3D scanning has become an essential tool for architects and construction professionals,...

The World’s Tallest 3D-Printed Building Rises in Switzerland

Tor Alva, or The White Tower, in Mulegns, Switzerland, sets a global...

Exploring 3D Printing in Architecture: How It’s Transforming Design and Construction

Discover how 3D printing is revolutionizing architecture by enhancing creativity, efficiency, and...

Sustainable 3D Printing with Clay: Revolutionizing Architecture Construction Material

Discover how 3D printing is revolutionizing architecture by combining the timeless advantages...

Leave a comment