- Home

- Articles

- Architectural Portfolio

- Architectral Presentation

- Inspirational Stories

- Architecture News

- Visualization

- BIM Industry

- Facade Design

- Parametric Design

- Career

- Landscape Architecture

- Construction

- Artificial Intelligence

- Sketching

- Design Softwares

- Diagrams

- Writing

- Architectural Tips

- Sustainability

- Courses

- Concept

- Technology

- History & Heritage

- Future of Architecture

- Guides & How-To

- Art & Culture

- Projects

- Interior Design

- Competitions

- Jobs

- Store

- Tools

- More

- Home

- Articles

- Architectural Portfolio

- Architectral Presentation

- Inspirational Stories

- Architecture News

- Visualization

- BIM Industry

- Facade Design

- Parametric Design

- Career

- Landscape Architecture

- Construction

- Artificial Intelligence

- Sketching

- Design Softwares

- Diagrams

- Writing

- Architectural Tips

- Sustainability

- Courses

- Concept

- Technology

- History & Heritage

- Future of Architecture

- Guides & How-To

- Art & Culture

- Projects

- Interior Design

- Competitions

- Jobs

- Store

- Tools

- More

Best 3D Printers for Architectural Model Making

Looking for the best 3D printer for architectural models? This guide reviews five top printers for architects, from the high-detail Formlabs Form 3+ resin printer to budget-friendly options like Prusa MK4. Includes FDM vs resin comparison, specs, pricing, workflow tips, and material recommendations for professional model making.

Table of Contents Show

- Top 5 Best 3D Printers for Architectural Models in 2026

- FDM vs. Resin: Which 3D Printing Technology for Your Architectural Models?

- How to Choose the Right 3D Printer for Architects

- From CAD to Physical Model: The 3D Print Arch Workflow

- Best Materials for 3D Printed Architectural Models

- 3D Printing Tips for Architects: Getting Professional Results

- Why Every Architecture Studio Needs a 3D Printer

Finding the best 3D printer for architectural models can transform how you design, present, and communicate building concepts. 3D printed architectural models serve as a powerful representation method, bridging the gap between digital design and physical reality. With an architecture printer on your desk, you can quickly prototype buildings in professional presentations, test design variations, and refine concepts before construction begins.

Unlike handmade models crafted from foam board or basswood, a 3D printer for architects replicates complex geometries that would otherwise take days to build by hand. Architectural models 3D printing has become standard practice at firms like Renzo Piano Building Workshop and Laney LA, where overnight prints replace weeks of manual labor. A reliable 3D printer helps architects turn digital imagination into physical reality, and the right machine depends on your studio’s size, budget, and project type.

In this guide, we review the best 3D printers for architects in 2026, compare FDM and resin technologies, and share practical advice for choosing a 3D printer for architectural models that fits your workflow.

| Printer | Technology | Build Volume | Layer Resolution | Approx. Price (USD) | Best For |

|---|---|---|---|---|---|

| Formlabs Form 3+ | SLA (LFS Resin) | 145 × 145 × 185 mm | 25–300 µm | ~$3,499 | High-detail facade & interior models |

| Ultimaker S5 | FDM (FFF) | 330 × 240 × 300 mm | 20–600 µm | ~$5,995 | Large-scale models & multi-material |

| Prusa i3 MK4 | FDM | 250 × 210 × 220 mm | 50–350 µm | ~$799 | Budget-friendly quality for students & studios |

| Anycubic Photon Mono X 6K | MSLA (LCD Resin) | 197 × 122 × 245 mm | 10–200 µm (Z) / 34 µm (XY) | ~$300–$659 | Ultra-detailed ornamental models |

| Creality CR-10 Smart Pro | FDM | 300 × 300 × 400 mm | 100–400 µm | ~$799 | Large urban design & site models |

Top 5 Best 3D Printers for Architectural Models in 2026

Each printer below has been selected based on print quality, build volume, material options, and how well it serves typical architectural workflows. Whether you need a detailed facade study or a full site model, one of these machines will fit your needs.

Formlabs Form 3+

The Formlabs Form 3+ is one of the leading resin-based 3D printers for architects who value high-detail and smooth finishes. Its Low Force Stereolithography (LFS) technology ensures precision down to the smallest architectural details, making it perfect for facade elements, miniature interiors, and intricate structural parts. Resin models produced on the Form 3+ have a professional, polished look with minimal post-processing needed.

The printer also offers a wide range of resin materials, including standard, durable, flexible, and even transparent options for different project needs. Firms like Renzo Piano Building Workshop (RPBW) use Formlabs SLA printers to produce models overnight when design changes happen rapidly. With an intuitive interface and consistent reliability, the Formlabs Form 3+ stands out as a professional-grade architecture printer ideal for offices that prioritize presentation-quality output.

| Technology | LFS (Low Force Stereolithography) |

| Build Volume | 145 × 145 × 185 mm (5.7 × 5.7 × 7.3 in) |

| Layer Thickness | 25–300 µm |

| XY Resolution | 85 µm laser spot size |

| Laser | 250 mW, 405 nm |

| Materials | 30+ resins (Standard, Durable, Flexible, Transparent, etc.) |

| Connectivity | Wi-Fi, Ethernet, USB |

| Software | PreForm (free) |

| Price | Starting at ~$3,499 |

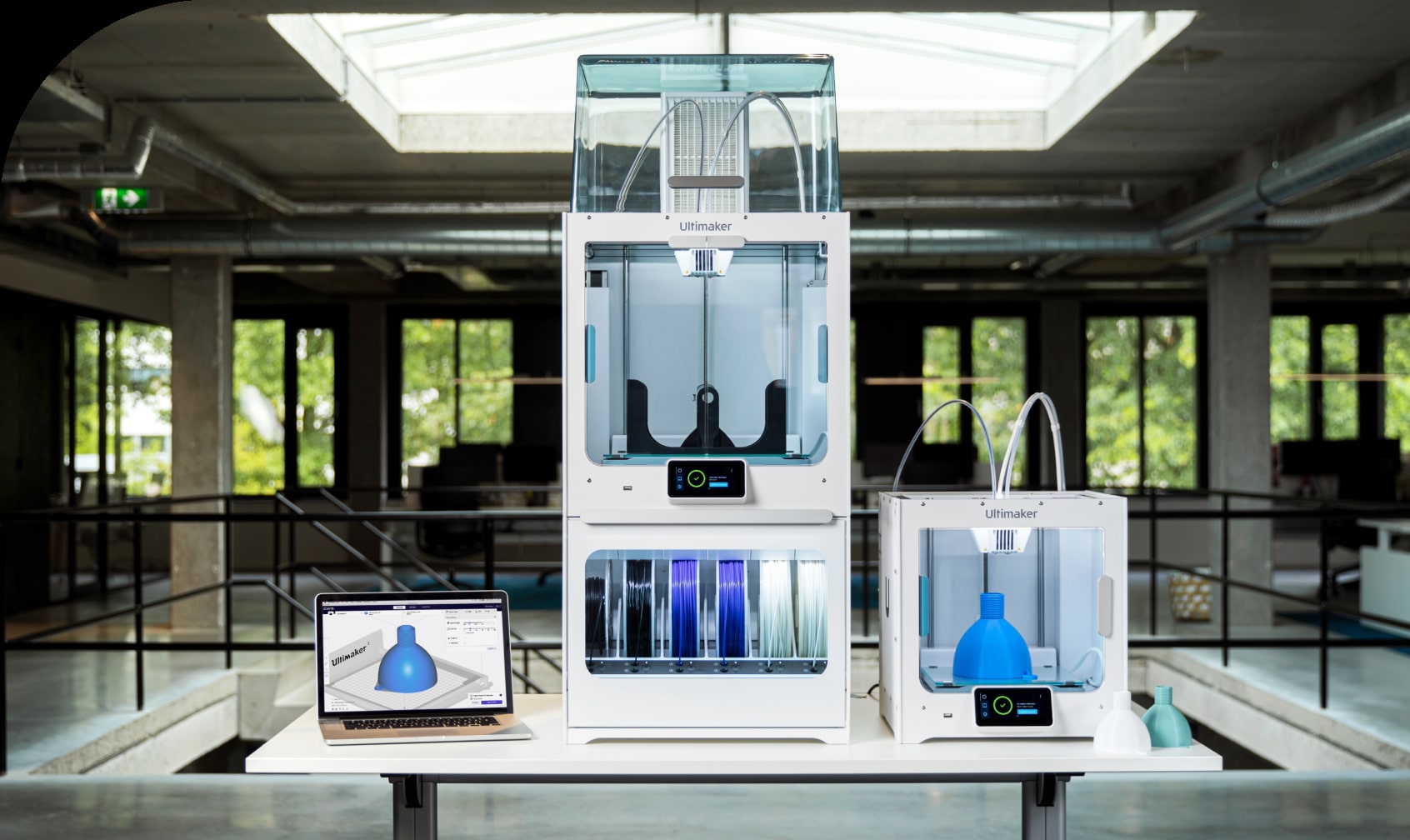

Ultimaker S5

The Ultimaker S5 is one of the most popular FDM (Fused Deposition Modeling) printers for professionals. Known for its large build volume (330 x 240 x 300 mm), it enables architects to 3D print bigger models or multiple parts in one session. This makes it highly efficient for offices working on large-scale projects or urban design layouts.

The S5 also supports dual extrusion, meaning you can print with two materials simultaneously. For example, combining structural PLA with dissolvable PVA support material allows you to achieve complex geometries without manual cleanup. Its open filament system provides flexibility with a wide range of third-party materials. According to a case study published by UltiMaker, the London-based firm Make Architects reduced model production costs by up to 90% after switching to Ultimaker printers. With reliable software integration through UltiMaker Cura, this best 3D printer for prototyping has become a go-to choice for architectural firms worldwide.

| Technology | FFF (Fused Filament Fabrication) |

| Build Volume | 330 × 240 × 300 mm (13 × 9.4 × 11.8 in) |

| Layer Resolution | 20–600 µm |

| Nozzle Sizes | 0.25 / 0.4 / 0.6 / 0.8 mm (swappable print cores) |

| Extruders | Dual extrusion |

| Max Nozzle Temp | 280 °C |

| Materials | 200+ (PLA, ABS, Nylon, CPE, PC, TPU, PVA, composites) |

| Connectivity | Wi-Fi, Ethernet, USB |

| Software | UltiMaker Cura (free) |

| Price | Starting at ~$5,995 |

Prusa i3 MK4

The Prusa i3 MK4 is a highly affordable yet professional 3D printer, making it popular among architects, students, and small studios. Known for its reliability, it provides excellent print quality for its price point and is user-friendly with automatic bed leveling, filament sensors, and fast setup.

It supports a wide variety of filaments, including PLA, PETG, and ABS, making it versatile for creating models of different textures and strength levels. The open-source PrusaSlicer software gives you full control over print parameters, and an active online community shares profiles optimized for architectural printing. If you are a student or run a small practice looking for the best 3D printer for architectural models on a budget, the Prusa MK4 offers an ideal balance of quality, versatility, and cost.

| Technology | FDM (Fused Deposition Modeling) |

| Build Volume | 250 × 210 × 220 mm (9.8 × 8.3 × 8.7 in) |

| Layer Resolution | 50–350 µm |

| Nozzle Diameter | 0.4 mm (interchangeable) |

| Extruder | Nextruder (direct drive, load cell sensor) |

| Materials | PLA, PETG, ABS, ASA, Flex, Nylon, Composites |

| Connectivity | USB-C, Ethernet, Wi-Fi (optional) |

| Software | PrusaSlicer (free, open-source) |

| Price | Starting at ~$799 |

Anycubic Photon Mono X 6K

The Anycubic Photon Mono X 6K is a resin printer designed for high-resolution 3D printing architecture models. With its 6K monochrome screen delivering 34 µm XY resolution, it produces extremely detailed architectural models ideal for facade ornamentation, furniture prototypes, and intricate scale designs.

Its printing speed is significantly faster compared to older resin printers, making it a good fit for rapid prototyping needs. At a price range of $300 to $659, this 3D printer architecture tool offers remarkable value. Combined with reliable results and an affordable entry point, the Photon Mono X 6K has become a strong competitor in the resin printing market and an excellent choice for studios producing 3D printed architectural model pieces that demand fine detail.

| Technology | MSLA (LCD-based UV Resin) |

| Build Volume | 197 × 122 × 245 mm (7.8 × 4.8 × 9.6 in) |

| Screen | 9.25″ 6K Mono LCD (5760 × 3600 px) |

| XY Resolution | 34 µm |

| Z Layer Thickness | 10–200 µm |

| Light Source | Matrix UV LED (405 nm), 30–100% adjustable |

| Contrast Ratio | 350:1 |

| Materials | 405 nm UV resins (standard & specialty) |

| Connectivity | USB |

| Price | Starting at ~$300–$659 |

Creality CR-10 Smart Pro

The Creality CR-10 Smart Pro is a large-format FDM printer designed for bigger and more detailed prints. Its 300 x 300 x 400 mm build volume is suitable for large-scale architectural models or urban design layouts. With features like Wi-Fi connectivity, touch-screen controls, and smart auto-leveling, it is both powerful and user-friendly.

Its compatibility with different filament types allows architects to experiment with different textures and finishes, from wood-fill PLA for realistic massing models to carbon fiber composites for structural prototypes. As a budget-friendly but capable option, the CR-10 Smart Pro makes large-scale prototyping more accessible for studios that regularly produce site models or neighborhood-scale presentations.

| Technology | FDM (Fused Deposition Modeling) |

| Build Volume | 300 × 300 × 400 mm (11.8 × 11.8 × 15.7 in) |

| Layer Resolution | 100–400 µm |

| Nozzle Diameter | 0.4 mm, 1.75 mm filament |

| Extruder | All-metal direct drive (Sprite) |

| Max Nozzle Temp | 300 °C |

| Materials | PLA, ABS, PETG, TPU, PA, Carbon Fiber, Wood |

| Connectivity | Wi-Fi, Bluetooth, Ethernet, SD Card |

| Special Features | Built-in HD camera, LED light bar, 4.3″ touchscreen |

| Price | Starting at ~$799 |

FDM vs. Resin: Which 3D Printing Technology for Your Architectural Models?

Choosing between FDM and resin technology is one of the first decisions you will face when selecting a 3D printer for architectural models. Each technology excels in different scenarios, and many professional studios keep one of each type to cover the full range of model-making needs. The table below breaks down how these technologies compare across the factors that matter most to architects.

| Feature | FDM (Ultimaker S5, Prusa MK4, Creality CR-10) | Resin / SLA (Formlabs Form 3+, Anycubic Mono X 6K) |

|---|---|---|

| Surface Detail | Visible layer lines (good for massing models) | Ultra-smooth surfaces (ideal for presentation models) |

| Build Volume | Generally larger (up to 300 × 300 × 400 mm) | Generally smaller (up to ~200 × 200 × 250 mm) |

| Material Cost | Lower (~$20–$50/kg filament) | Higher (~$35–$150/liter resin) |

| Post-Processing | Minimal (remove supports, optional sanding) | Required (washing + UV curing) |

| Best For | Massing models, site layouts, large-scale prototypes | Facade details, furniture, intricate ornamental elements |

| Safety | Low concern (use ventilation for ABS) | Requires gloves & ventilation (liquid resin is toxic) |

In practice, FDM printers work best for early-stage concept models and large site plans where speed and size matter more than surface finish. Resin printers shine when you need to present intricate details to clients, such as ornamental facades, custom furniture, or interior layouts at 1:50 scale or smaller. Many studios start with an affordable FDM machine like the Prusa MK4 and later add a resin printer like the Anycubic Photon Mono X 6K for presentation work.

How to Choose the Right 3D Printer for Architects

Selecting the best 3D printer for architects depends on several practical factors. Before purchasing, consider the following criteria to match your studio’s real-world needs.

Build Volume and Model Scale

Think about the typical scale you work at. If you regularly produce 1:100 or 1:200 site models, a large-format FDM printer like the Creality CR-10 Smart Pro (300 x 300 x 400 mm) lets you print substantial sections in one piece. For detail-focused 1:50 interior models, a smaller resin printer with high resolution may be the better investment. Keep in mind that most 3D printed architectural models larger than the print bed can be divided into sections and assembled after printing.

Resolution and Surface Quality

Resolution determines how fine your architectural details will appear. For presentation models where clients will examine window mullions, balustrades, and surface textures up close, aim for 25 to 50 µm layer height (achievable with SLA/MSLA printers). For study models where overall massing and spatial relationships matter more, 100 to 200 µm on an FDM machine works well. As a reference, a printer with 25 µm resolution can render individual window panes clearly at 1:100 scale.

Material Compatibility

Different projects call for different materials. PLA is the most common filament for architectural models because it is easy to print, affordable, and produces clean white surfaces that photograph well. PETG and ABS offer greater strength for models that need to survive transport. Resin printers expand your options further with transparent, flexible, and castable materials. If you plan to experiment with wood-fill, stone-fill, or carbon fiber filaments, choose an FDM printer with an all-metal hotend and a maximum nozzle temperature above 260 °C.

Software and CAD Workflow

Your 3D printer needs to integrate with your existing design software workflow. Most architectural CAD programs (Rhino, Revit, ArchiCAD, SketchUp) can export STL or OBJ files suitable for 3D printing. Slicer software like UltiMaker Cura (for FDM) or Formlabs PreForm (for SLA) then prepares these files for printing. Choose a printer whose slicer supports automatic support generation and offers profiles optimized for architectural work.

From CAD to Physical Model: The 3D Print Arch Workflow

Understanding the 3D print arch workflow helps you get better results from your architecture printer. Here is a step-by-step overview of the process most studios follow when producing 3D printing architecture models.

Start by preparing your 3D model in your preferred CAD software. Simplify the geometry where possible, remove internal faces, and ensure the mesh is watertight. Next, decide on scale and orientation. A common approach is to split large models into sections that fit the build plate, using alignment pins or keyed joints for assembly. Import the STL file into your slicer, set layer height based on the required detail level, and generate supports where needed. After printing, remove supports carefully, sand visible surfaces, and apply primer and paint as desired. Post-processing techniques like filler primer spray and wet sanding with 400 to 800 grit paper can dramatically improve the final appearance of FDM prints.

For resin prints, the post-processing sequence includes washing in isopropyl alcohol, UV curing under a dedicated lamp, and then sanding and painting. The entire cycle from digital file to finished model typically takes 1 to 3 days depending on size and complexity, according to Zortrax’s architecture application guide.

Best Materials for 3D Printed Architectural Models

Choosing the right material affects both the look and durability of your finished model. Here is a summary of the most commonly used materials for 3D printing architectural models.

FDM Filaments for Architecture

PLA remains the default choice for most architectural prints. It produces a matte white finish, requires no heated enclosure, and costs roughly $20 to $30 per kilogram. PETG is a good alternative when you need slightly higher impact resistance, for instance for models that will be transported to client meetings. Wood-fill and stone-fill PLA composites can simulate natural material textures, which adds realism to model making presentations. For structural elements or parts that need to survive repeated handling, consider ABS or ASA printed in an enclosed chamber.

Resin Materials for Architecture

Standard grey or white resin is the starting point for most resin prints. Transparent resin works well for glazing elements, allowing you to show interior spaces through exterior walls. Durable and tough resins from Formlabs offer ABS-like strength for functional prototypes. Keep in mind that all resin materials require proper ventilation and personal protective equipment (gloves and safety glasses) during handling.

3D Printing Tips for Architects: Getting Professional Results

Getting clean, professional results from any 3D printer for architects requires attention to a few practical details that go beyond default slicer settings.

Scale your model carefully. For 1:100 models, wall thicknesses below 0.8 mm may not print reliably on FDM machines. On resin printers, you can go as thin as 0.3 mm for delicate elements like railings. Print orientation matters too: angling a building at 45 degrees on the build plate can reduce the need for support structures on overhanging facades.

When printing multi-part models for assembly, add 0.2 mm tolerance to connection points to account for dimensional variations. Use cyanoacrylate (super glue) for bonding PLA parts, and UV-cure adhesive for resin pieces. For a uniform finish across assembled sections, apply a coat of filler primer before painting.

Consider investing in a basic post-processing kit: fine-grit sandpaper (320 to 800 grit), spray primer, model paint, and a cutting mat. These simple tools turn a rough 3D print into a presentation-ready 3D printed architectural model that communicates your design intent clearly.

Why Every Architecture Studio Needs a 3D Printer

For architects, a 3D printer is more than just a piece of equipment. It enhances creativity, speeds up workflow, and improves communication of design ideas. Complex geometries that are difficult to visualize in drawings can be brought to life with precise detail and scale accuracy.

The ability to print models overnight means design iterations that once took weeks can now happen in a single day. According to the UltiMaker case study on Make Architects, switching from traditional timber models to 3D printing reduced both production time and cost by approximately 90%. This frees up budget for more iterations and allows teams to explore bolder design concepts without worrying about model-making labor costs.

3D-printed models also allow clients and stakeholders to engage with designs in a more tangible and interactive way. You can remove roof sections to reveal interior layouts, print at multiple scales, or create modular pieces that snap together. This hands-on interaction builds stronger client confidence and leads to more informed decision-making.

With the growing demand for sustainable architecture, many 3D printers now support eco-friendly materials like biodegradable PLA and recycled filaments that reduce waste. This makes it possible for architects to prototype responsibly while still exploring bold and innovative concepts. Technologies like VR in architecture complement 3D printed models by offering immersive digital walkthroughs alongside physical representations, giving clients the full picture of a proposed design.

Investing in the right 3D printer means investing in the future of architectural creativity. Whether you choose a high-detail resin printer like the Formlabs Form 3+ or a versatile FDM model like the Ultimaker S5 and budget-friendly Prusa i3 MK4, there are options for every studio size and need. When selecting a 3D printer, consider build volume, material compatibility, resolution, and ease of use to find the machine that best supports your practice.

Prices mentioned in this article are approximate and may vary by region, retailer, and current promotions. Always verify specifications with the manufacturer before purchasing.

- 3d print arch

- 3d printed architectural model

- 3d printer architecture

- 3d printer for architects

- 3d printer for architectural models

- 3D printers for architecture

- 3d printing architecture models

- affordable 3D printers for architecture students

- Anycubic Photon Mono X 6K architecture

- arch d printer

- architectural model 3D printing

- architectural models 3d printing

- architectural scale models 3D printing

- architecture printer

- best 3D printer for architects

- best 3d printer for architectural models

- best 3d printer for prototyping

- best printer for architects

- Creality CR-10 Smart Pro for architects

- FDM 3D printers for architects

- Formlabs Form 3+ review

- high-resolution 3D printers for architects

- large format 3D printers for architecture

- printer for architects

- professional 3D printers for architects

- Prusa i3 MK4 for architectural models

- rapid prototyping for architects

- resin 3D printers for architecture

- Ultimaker S5 for architects

1 Comment

Submit your architectural projects

Follow these steps for submission your project. Submission FormLatest Posts

25 Best AI Architectural Rendering Tools in 2026

AI is revolutionizing architectural visualization in 2026, enabling faster iterations, richer creativity,...

Visualizing the Invisible: How 3D Rendering Revolutionizes Basement Waterproofing Design

Table of Contents Show The Hidden Architecture of Water ManagementBeyond Static Plans:...

Revolutionizing Design: The Impact of VR in Architecture

Discover how virtual reality (VR) is transforming architecture by enhancing design visualization...

How 3D Product Visualization Software Is Redefining the Future of Design Presentation

In the evolving world of architecture, product design, and interior visualization, 3D...

So, let me get this straight: 3D printing is like magic for architects? I mean, one minute you’re doodling on a napkin, and the next you have a mini Eiffel Tower that doesn’t look like it’s been through a blender! I just hope my coffee cup doesn’t turn into a 3D model by accident. Also, what’s up with the price tags? Who knew turning ideas into reality could cost more than my car?