- Home

- Articles

- Architectural Portfolio

- Architectral Presentation

- Inspirational Stories

- Architecture News

- Visualization

- BIM Industry

- Facade Design

- Parametric Design

- Career

- Landscape Architecture

- Construction

- Artificial Intelligence

- Sketching

- Design Softwares

- Diagrams

- Writing

- Architectural Tips

- Sustainability

- Courses

- Concept

- Technology

- History & Heritage

- Future of Architecture

- Guides & How-To

- Art & Culture

- Projects

- Interior Design

- Competitions

- Jobs

- Store

- Tools

- More

- Home

- Articles

- Architectural Portfolio

- Architectral Presentation

- Inspirational Stories

- Architecture News

- Visualization

- BIM Industry

- Facade Design

- Parametric Design

- Career

- Landscape Architecture

- Construction

- Artificial Intelligence

- Sketching

- Design Softwares

- Diagrams

- Writing

- Architectural Tips

- Sustainability

- Courses

- Concept

- Technology

- History & Heritage

- Future of Architecture

- Guides & How-To

- Art & Culture

- Projects

- Interior Design

- Competitions

- Jobs

- Store

- Tools

- More

How to Read Construction Drawings: A Practical, Field-Tested Guide

How to read construction drawings: a clear, step-by-step guide to decode sheets, scales, symbols, and specs—spot clashes, cut rework, and build as designed.

Table of Contents Show

- Understand What Construction Drawings Include

- Decode The Sheet: Title Blocks, Revisions, And Legends

- Master Scales, Grids, And Dimensions

- Read Views The Right Way: Plans, Elevations, Sections, And Details

- Connect Drawings With Specs, Schedules, And Notes

- Coordinate Across Disciplines And Catch Conflicts

- Conclusion

If you’ve ever unrolled a set and wondered where to start, you’re not alone. Learning how to read construction drawings is about finding the story in lines, symbols, and notes, so we can build exactly what was intended, on time and without costly rework. In this guide, we’ll walk through the parts of a drawing set, how to decode sheets, and how to connect drawings with specs, so we can navigate confidently from concept to punch list.

Understand What Construction Drawings Include

Types Of Drawings (Architectural, Structural, MEP, Civil)

A full set covers multiple disciplines, each telling a slice of the same story:

- Architectural (A): plans, elevations, sections, details, interiors, finishes.

- Structural (S): foundations, framing plans, rebar, structural details.

- MEP (M, E, P, FP): mechanical ductwork and HVAC, electrical power/lighting/single-line, plumbing piping/fixtures, fire protection.

- Civil (C): site grading, utilities, stormwater, paving.

We’ll also see specialty sheets (ID for interiors, L for landscape, FA for fire alarm, etc.).

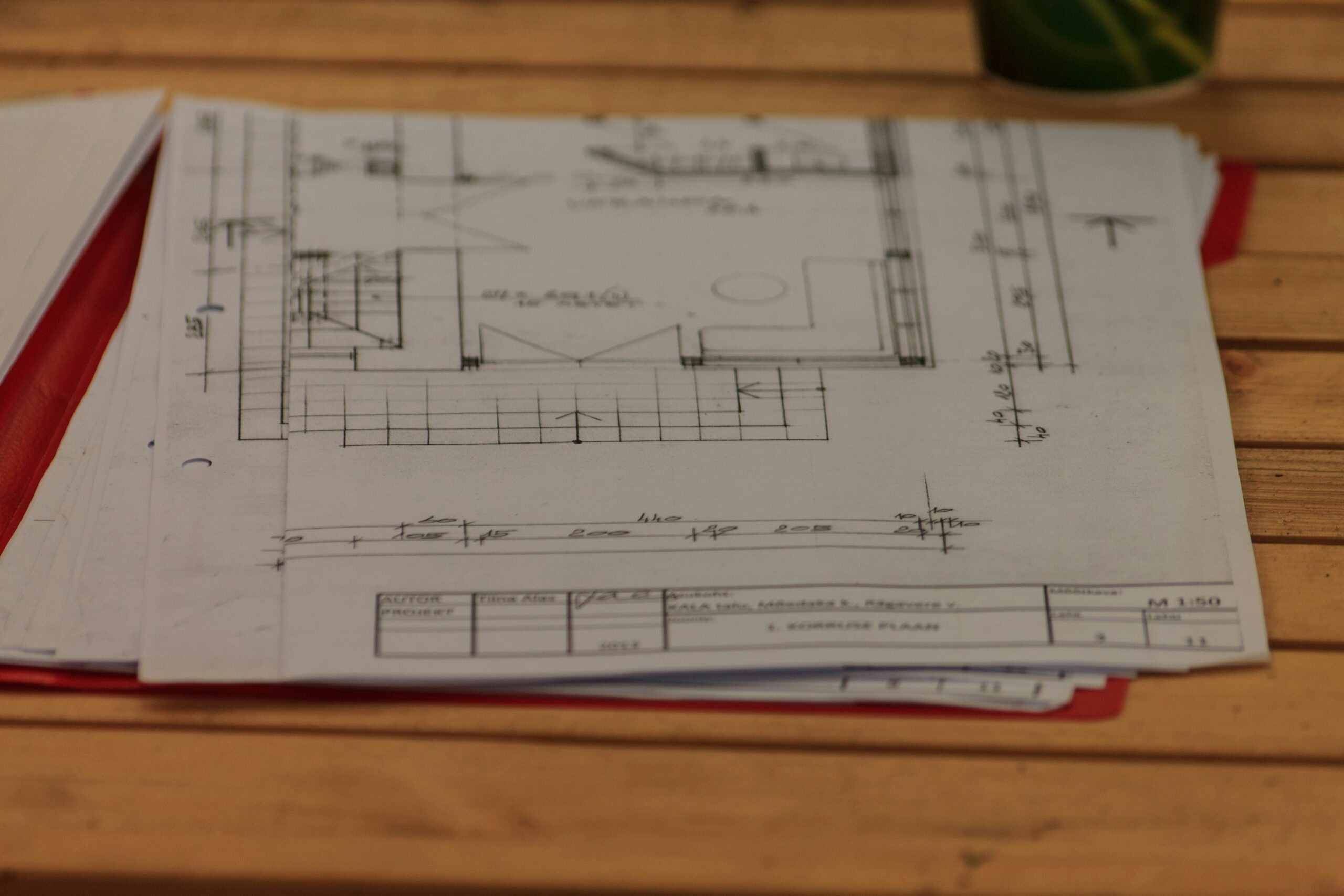

Sheets, Sets, And How They Fit Together

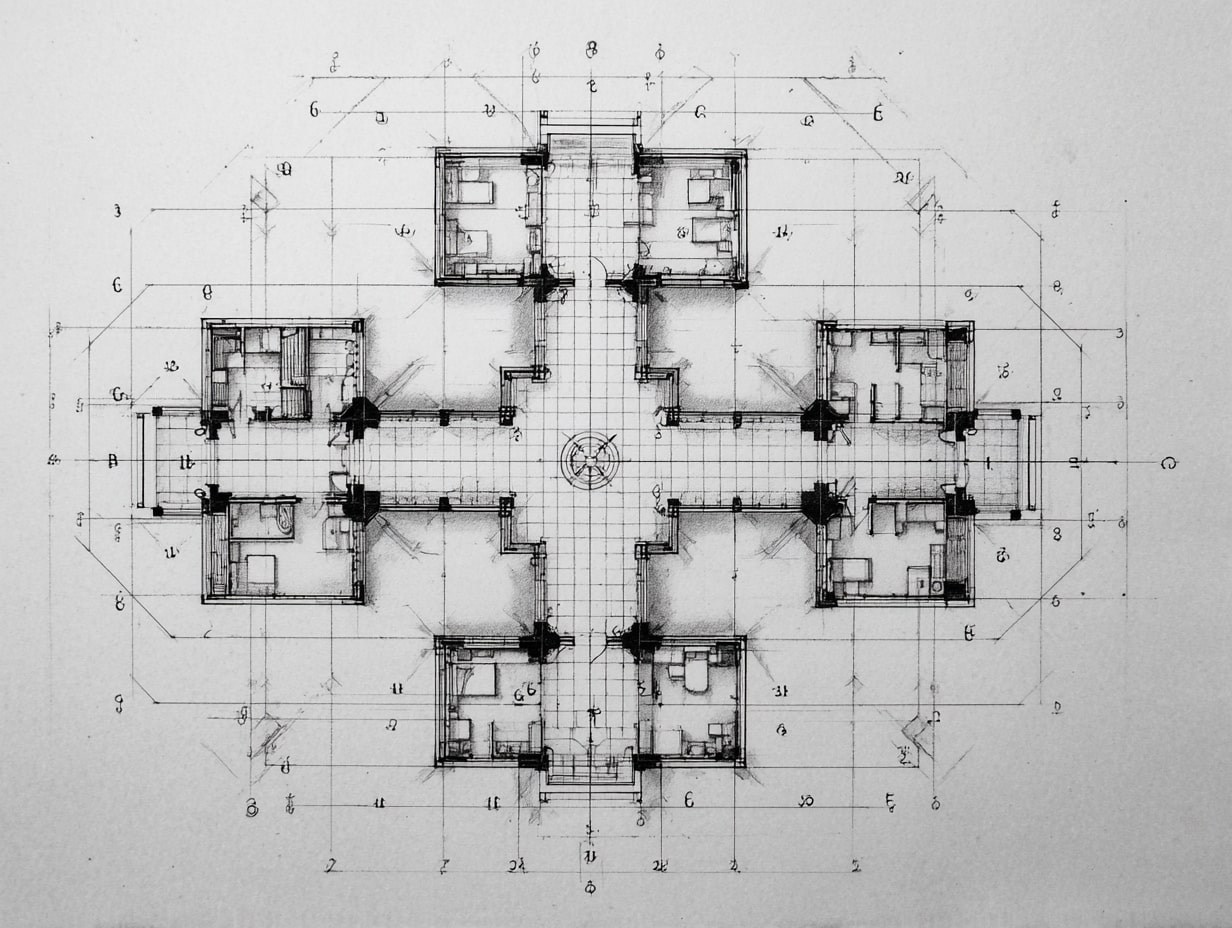

Sheets are organized to move from big picture to fine detail. A typical flow: cover sheet and code plans → overall site and floor plans → enlarged plans → elevations and sections → details → schedules. Naming often follows A-101 (plan), A-201 (elevation), S-301 (details). Keep a mental map: plans show “where,” elevations show “what it looks like,” sections show “how it’s built,” and details show “exactly how parts meet.”

Decode The Sheet: Title Blocks, Revisions, And Legends

Title Block Fields To Check First

Before anything else, we check the title block:

- Project name and address

- Sheet title and number

- Scale and north arrow (if applicable)

- Designer/engineer of record, seals, and issue date

- Sheet issue set (bid, permit, IFC, addendum)

- Drawing status notes (preliminary vs. for construction)

These tell us whether the sheet is current and what contract it belongs to.

Revision Clouds And Issue Histories

Revisions are marked with clouds and delta symbols. The delta number references a revision entry in the title block with a date and description (e.g., Rev 3: Addendum 2 door changes). We always cross-check the revision index against our set logs, so a clouded door size on A-701 matches the latest coordination on the door schedule and any addenda.

Legend, Abbreviations, And Symbols

Legends decode line types and symbols (e.g., partition types, diffusers, outlets). Abbreviation lists prevent guesswork: AFF (above finish floor), T.O.S. (top of steel), CLR (clear). If a symbol isn’t in the legend, we look for a general note or a discipline-specific legend on another sheet.

Master Scales, Grids, And Dimensions

Using Scales And Scale Bars

Check the stated scale and verify with the scale bar, especially when printing at half-size. Common scales: 1/8″ = 1′-0″ for plans, 3/8″ or 1/2″ for enlarged plans, and 1 1/2″ details. If dimensions conflict with scaled distances, dimensions win.

Grid Lines And Control Points

Grid lines (A, B, C… and 1, 2, 3…) anchor layout. We set out columns, walls, and shafts by grid intersections and verify with survey control points and benchmarks. On site, control is king, tie layout to the benchmark elevation and the project coordinate system before pulling tapes.

Reading Dimensions, Elevations, And Tolerances

Look for dimension strings: overall → major bays → openings. Elevations reference a datum (often 0′-0″ at finished floor). Tolerances matter: a door frame rough opening might require +3/8″, and structural camber or slab flatness (FF/FL) can affect built-ins. When in doubt, note the tolerance in our pre-install checklist.

Read Views The Right Way: Plans, Elevations, Sections, And Details

Plan Views And Orientation

Start with the north arrow. Confirm floor, building wing, and orientation tags. Plans show walls, openings, fixtures, and references to other views. We trace flow: entry → corridor → room, then jump to enlarged plans where callouts indicate.

Elevations And Callouts

Elevations translate plan lines into faces. Callouts show material tags, finish heights, and datum lines. Window head and sill heights, parapet caps, and alignments across façades are easier to spot here than on plan.

Sections, Details, And Reference Bubbles

Section marks cut through the building to show assemblies: structure, insulation, vapor barriers, flashings. Reference bubbles pair a detail number with a sheet number (e.g., 5/A-501). Follow these breadcrumbs to understand how the roof ties into the wall or how waterproofing wraps at a curb.

Connect Drawings With Specs, Schedules, And Notes

General Notes Vs. Keynotes

General notes apply to the whole sheet or discipline. Keynotes are numbered tags tied to a list (e.g., K-12: Type ‘X’ gypsum at shaft walls). We read both together: a keynote often relies on a general note for installation standard.

Door, Window, And Finish Schedules

Schedules consolidate data: door types, hardware sets, handing: window types and glazing: finish codes per room. When a door tag says D-117, we jump to the door schedule for size, rating, and hardware, then cross-check life-safety sheets.

Drawing–Specification Coordination

Drawings show quantity and location: specs define quality and performance. We align details with CSI specs (e.g., 08 14 00 for wood doors). If a detail calls for WRB A but Section 07 27 26 lists WRB B, we flag it. BIM and architectural languages can help here, architectural languages like IFC, GDL, and gbXML formalize model data and properties, making it easier to track assemblies across drawings and specifications without translation errors.

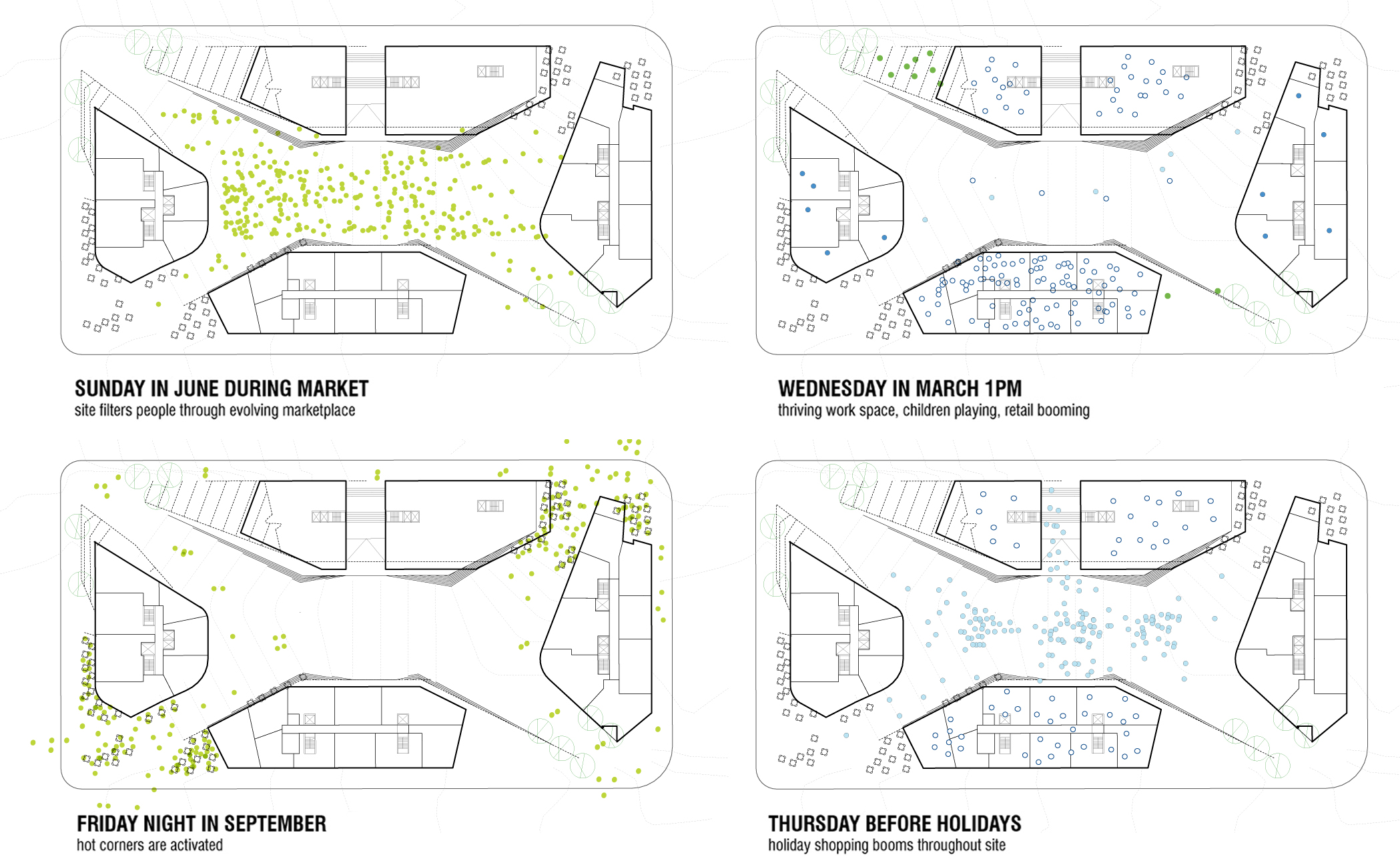

Coordinate Across Disciplines And Catch Conflicts

Typical Clash Points To Check

- Ducts vs. beams at tight soffits

- Pipe slopes vs. slab drops

- Sprinkler heads vs. light fixtures and ceiling layouts

- Door swings vs. radiators or card readers

- ADA clearances at restrooms and casework

We walk the model or overlay PDFs to catch these early.

RFIs, Submittals, And Field Clarifications

When something’s unclear, we issue an RFI with a markup referencing exact sheets and details. Submittals should mirror the specified products and note any deviations. Field clarifications, sketches or bulletin drawings, must be folded back into our working set.

As-Builts And Record Drawings

We redline changes during construction: penetrations moved, valve locations adjusted, outlet heights shifted. Those as-builts become record drawings for turnover and future maintenance.

Conclusion

Reading construction drawings isn’t guesswork, it’s a process. We start with the title block, verify revisions, anchor to scales and grids, then follow callouts to details while cross-referencing specs and schedules. Keep an eye on coordination hot spots, document questions fast, and capture changes as they happen. Do this consistently and we’ll cut rework, protect budgets, and deliver exactly what was designed, no surprises when the punch list shows up.

- analyzing construction drawings

- basic construction drawing skills

- construction blueprints guide

- construction documentation reading

- construction drawing guide

- construction drawings for beginners

- construction drawings interpretation

- construction floor plan reading

- construction plan reading tips

- construction schematics understanding

- construction site drawing guide

- field guide to construction drawings

- field-tested construction drawings

- how to read construction drawings

- interpreting construction drawings

- learn to read construction drawings

- practical construction drawing tips

- reading architectural drawings

- step-by-step construction drawing guide

- understanding construction plans

Submit your architectural projects

Follow these steps for submission your project. Submission FormLatest Posts

What Architects Need to Know About LiDAR Before Your Next Renovation Project

Table of Contents Show The Real Problem With Traditional As-Built DrawingsWhat Exactly...

Modernism vs Postmodernism: How Order and Ornament Shape Architectural Meaning

Modernism and Postmodernism represent two fundamentally different ways of understanding architecture’s role...

Tips to Keep Your Belongings Safe from Heat, Cold, and Humidity

Table of Contents Show Pack everything appropriatelyWhat to do if you plan...

8 Smart Steps to Take Before Buying a Home for Sale

Table of Contents Show 1. Assess Financial Readiness2. Research Neighborhoods Thoroughly3. Be...

Leave a comment